Airbus and Boeing are laying the groundwork for unprecedented production increases of their next-generation single-aisle aircraft, targeting rates of up to 100 planes per month. Both manufacturers are actively researching advanced thermoplastic composite materials and robotic assembly techniques to streamline manufacturing processes and meet soaring demand. This marks a significant shift from the aluminum-based construction that has dominated their bestselling Boeing 737 and Airbus A320 families.

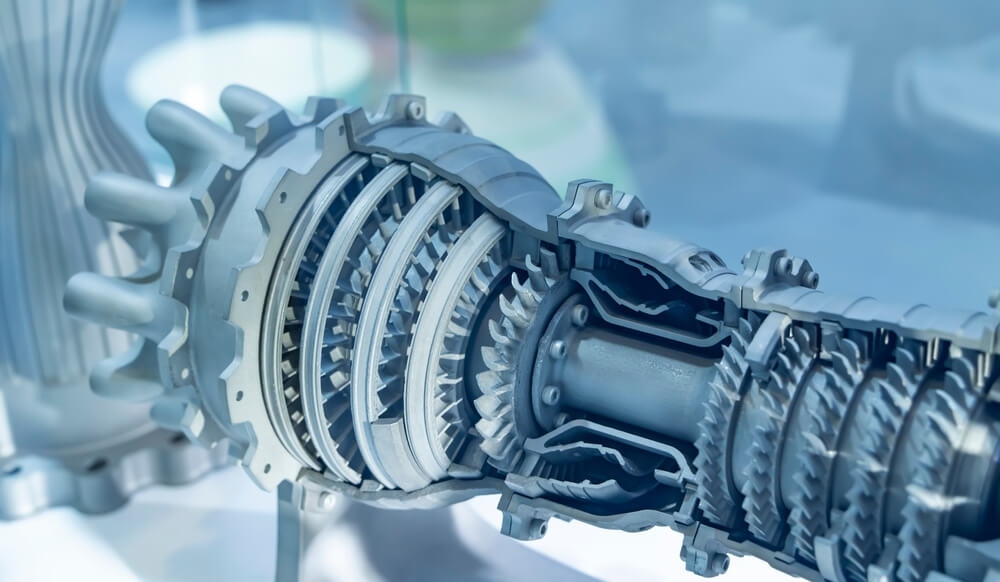

Thermoplastics represent a breakthrough technology in aerospace manufacturing. Unlike traditional thermoset composites, which require time-consuming curing in autoclaves, thermoplastics can be reheated, reshaped, and welded using advanced techniques like ultrasound. This innovation reduces production time and weight while enabling seamless aerodynamic designs. Lukas Raps of the German Aerospace Centre emphasized the material’s adaptability, stating, “You can melt it and reshape it in any way you like.”

Both companies showcased their progress at the JEC World composites conference in Paris, where Airbus, GKN, and partners presented sections of the world’s largest thermoplastic fuselage structure as a technology demonstrator While this structure was not intended for flight, it highlights the potential of thermoplastics to revolutionize aircraft design and manufacturing.

Despite these advancements, challenges remain. Transitioning from traditional titanium fasteners to welded components will require extensive certification testing. Additionally, supply chain disruptions and delays in next-generation engine development could hinder production targets Analysts note that both Airbus and Boeing are pushing the limits of manufacturing capacity as they prepare suppliers for record-breaking output levels.

Industry experts believe that thermoplastics could play a critical role in addressing these challenges while enabling more efficient production processes. As competition intensifies globally, particularly from China, manufacturing capacity is expected to become as crucial as aircraft design in shaping the future of commercial aviation.